Choosing the Right Mix for Concrete Flatwork in Doral

Concrete Flatwork Doral

When selecting an optimum concrete mixture for flatwork in Doral, FL, we have to consider the special regional climate and demands on the work. Concrete flatwork is defined as all exterior concrete (parking lots, driveways, sidewalks, etc.) that must be able to handle the constant weight of traffic while being exposed to the high humidity, extreme temperatures, and possible salt damage from de-icing materials. Therefore, experienced contractors realize that proper mixture design will affect how well the flatwork performs over its lifespan, and therefore affect the level of maintenance required. The selection of adequate cement content, aggregates, and admixtures will help ensure that your flatwork installation meets both your functional needs (structural integrity) and visual expectations. As such, understanding these basic principles will allow you to make educated decisions regarding your concrete investment in Doral’s highly competitive construction marketplace.

Understanding the Basics of Concrete Mix Designs for Flatwork

For flatwork in South Florida, a key aspect of designing the right concrete mix is finding a balance between four fundamental elements: Portland cement, aggregates (sand and gravel), water, and chemical admixtures—so that it has all the characteristics you want. A critical factor in determining the strength and durability of your concrete is the water-to-cement (W/C) ratio. Optimal W/C ratios are usually found to be between 0.40 and 0.50 for most South Florida applications. When the W/C ratio is lower than this range, you get a stronger concrete; however, it could have a negative effect on workability. On the other hand, when you increase the W/C ratio, you will get better placement ease, but you will lose some long-term durability.

The type of aggregate used has a significant impact on the performance of your concrete, and for the climate of Doral, crushed limestone is the best option because it has very low thermal expansion and great bond characteristics. For the sand portion of the aggregate, it is normal for it to comprise 35-45 percent of the total aggregate volume, with the coarse aggregate making up the rest. As mentioned previously, the gradation and quality of both the sand and the coarse aggregates will greatly affect the workability, finishability, and durability of your concrete.

Required Compressive Strength for Different Types of Applications

Different types of flatwork applications have different required compressive strengths based on their intended use and load requirements. For example, a typical residential driveway would need to have a compressive strength of 3000 to 4000 PSI, since they will normally be subjected to standard vehicle weights and the traffic pattern associated with them. Commercial parking lots and applications requiring heavier loads, such as the Costa Del Sol Golf Club, may need to have compressive strengths of 4000 to 5000 PSI to account for the additional weight and traffic volume without premature degradation.

Typically, sidewalks and pedestrian ways can be constructed with 3000 PSI concrete, as long as they are designed and built with sufficient thickness and reinforcement. However, if an area is going to be accessed frequently by maintenance vehicles or if it is located in proximity to commercial developments, you may find that a higher-strength mix is warranted. Regardless of which mix is used, the compressive strength at 28 days is always the standard method for verifying compliance with specifications and quality control.

Climate-Specific Characteristics of Concrete Mixes

Because South Florida is in a subtropical climate zone, there are many environmental factors that demand that concrete mixes be designed to withstand the extreme heat, humidity, and fluctuating weather conditions that occur throughout the year. One of the most essential characteristics needed to protect the concrete from damage caused by freezing and thawing is air entrainment. In addition to providing freeze-thaw resistance, air entrainment also improves the workability of the fresh concrete mixture. The amount of air that should be entrained varies, depending on the size of the aggregate and the degree of exposure the finished surface will have to the environment. Typically, the recommended air content for exterior flatwork applications will be within the range of 4% to 7%.

Using heat-resistant aggregates will also help minimize thermal expansion problems that can cause cracking and joint problems in flatwork applications. There are several types of lightweight aggregate products available today, such as lightweight expanded clay aggregates or ceramic-based materials, that provide superior thermal properties while still maintaining the structural integrity of the aggregate. Using a reflective aggregate product will also help reduce the surface temperature of the concrete and improve the walking-surface comfort for pedestrians in areas surrounding cultural landmarks such as Our Lady of Guadalupe Church.

Durability and Moisture Resistance

The high humidity level present in Doral requires concrete mixes that have been formulated to resist moisture and, therefore, premature degradation and surface scaling. Supplemental cementitious materials (SCMs), such as fly ash or silica fume, can enhance the durability of the concrete by increasing the density and reducing the permeability of the hardened concrete, provided that they are properly incorporated into the mix design. SCMs will also contribute to the long-term strength gain and improved chemical resistance to environmental exposure of the hardened concrete.

Water-reducing admixtures will enable the contractor to achieve the desired workability while maintaining the low W/C ratio necessary for the durability of the concrete. High-range water reducers (HRWRs) will also enable the production of flowing concrete that will place easily into flatwork applications without segregation or bleeding issues. Therefore, selecting and dosing the correct admixture will assure optimal performance of the concrete in Doral’s varying seasonal conditions.

Admixture Selection and Use

Chemical admixtures add functionality to flatwork concrete in the challenging climate of South Florida. Corrosion-inhibiting admixtures become especially important for reinforced concrete applications located in areas exposed to the ocean, as salt spray can rapidly deteriorate the steel reinforcement. These specialty admixtures create protective barriers around the reinforcing steel while maintaining the strength and workability of the concrete.

Set-retarding admixtures will also help the contractor manage the placement of concrete during the hot weather conditions that exist in Doral’s summer months. The extended working time provided by these admixtures will enable the contractor to properly complete the finishing operations before the concrete sets and prevent the premature setting of the concrete, which can negatively affect the appearance and durability of the surface of the finished concrete. It is equally important for the contractor to carefully balance the retarding effects of these admixtures with the scheduling needs of the project to maintain efficient construction progress.

Reinforcing Fiber Options

Synthetic fiber reinforcement provides a cost-effective solution to crack control in flatwork applications without the added complexity of placing and finishing the traditional steel reinforcement. Synthetic polypropylene fibers will help to reduce plastic shrinkage cracking during the curing of the concrete while allowing the concrete to remain workable and finishable. Synthetic fibers are particularly useful in large-area pours common in commercial flatwork projects.

Steel fibers offer greater structural performance for high-traffic applications that require the ability to distribute loads effectively and to exhibit enhanced crack resistance. Steel fiber selection must take into consideration the finishing requirements of the job, as well as the potential for surface texture that may affect the aesthetic appearance of the finished surface. Proper fiber distribution throughout the concrete mix will provide consistent performance across the entire flatwork installation.

Quality Control/Testing Protocols

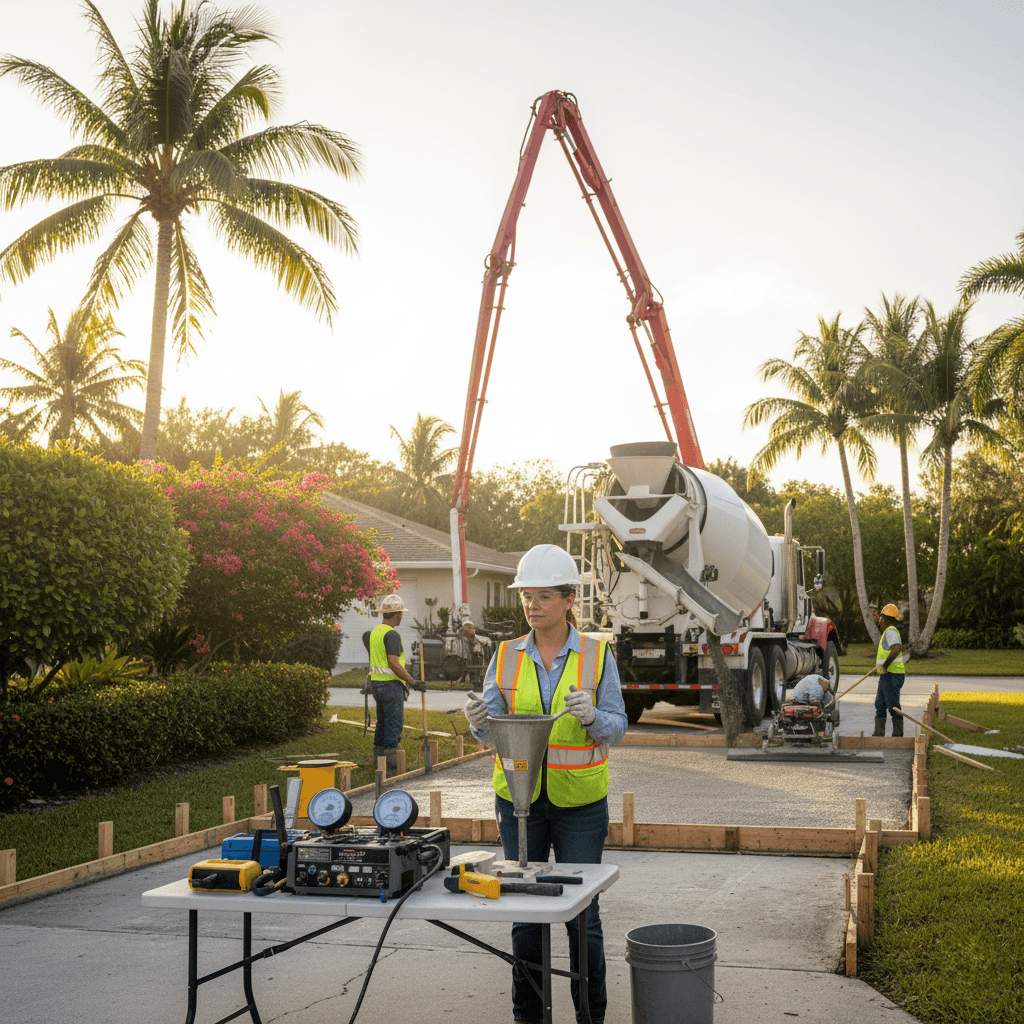

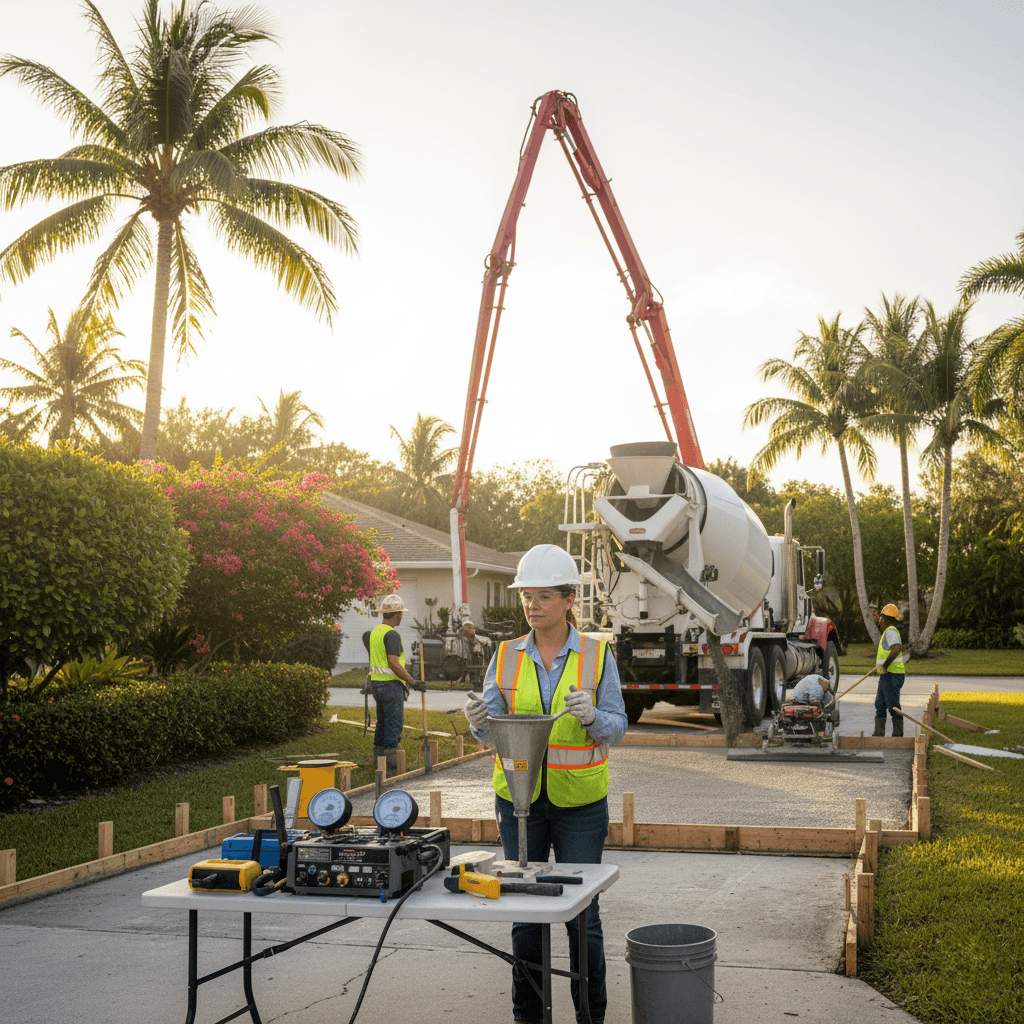

A comprehensive Quality Control program assures that the specified performance characteristics of the concrete mix are met and maintained throughout the construction process. Slump testing will verify that the workability of the concrete remains consistent, while air-content testing will confirm that the proper amount of air has been entrained into the concrete to provide adequate freeze-thaw resistance and workability for durable performance. Temperature monitoring will prevent the placement of heated concrete that will set quickly and become difficult to finish.

Standardized compression tests, performed on cylindrical samples, will provide definitive proof of whether the specified mix design meets the required performance criteria at 7, 14, and 28-day intervals. Additional testing may include rapid chloride permeability tests to determine the durability of the concrete in salt-exposure environments. Correct sampling and testing will ensure an accurate representation of the quality of the in-place concrete.

Field Verification Methods

Non-destructive testing methods provide a means of verifying the properties of the in-place concrete without damaging the structure. Rebound hammer testing will provide a quick estimate of the strength of the concrete, while penetration resistance testing will evaluate the surface hardness and curing effectiveness of the concrete. These field testing methods will supplement laboratory testing to provide comprehensive Quality Assurance throughout the construction process.

In rare cases, core sampling may be required, either for critical applications or when laboratory test results indicate potential problems with the quality of the concrete. Professional testing laboratories will analyze the various properties of the concrete, including compressive strength, density, and chloride-content measurements to support project acceptance and long-term performance predictions.

Economic Value of Optimizing Concrete Mixes

Concrete mixes optimized for flatwork applications provide significantly greater value over the long term, through extended service life and reduced maintenance, compared to conventional mixes. The higher upfront costs associated with premium aggregates, admixtures, and Quality Control testing will typically yield an additional 25-40 percent service life for flatwork installations. Considering the costs of maintenance and repairs, this extended performance represents a significant reduction in life-cycle costs compared to the frequent repairs and replacements required with conventional mixes.

Energy-Efficient Mixes

Additionally, energy-efficient concrete mixes that utilize thermal-resistant aggregates will reduce cooling costs for nearby structures while also providing a cooler walking surface for pedestrians. These benefits are particularly significant for commercial developments and public spaces where user comfort is a major factor affecting property values and utilization rates.

Environmental Impact Considerations

Sustainable concrete mixes formulated to utilize recycled aggregates and supplemental cementitious materials will reduce the environmental impact of the concrete while still maintaining the desired performance characteristics. The incorporation of fly ash and/or slag cement as a replacement for a portion of the Portland cement can reduce the Portland cement content of the mix by 15-30%, while enhancing the long-term durability characteristics of the hardened concrete. These sustainable alternatives will aid in achieving “Green Building” objectives, which are becoming increasingly prevalent in the development projects occurring in Doral.

Local Aggregate Sourcing

As mentioned earlier, utilizing locally sourced aggregates will reduce the transportation costs and environmental impact of the project, while also promoting the local economy. Miami-Dade County has an abundance of limestone deposits, which are ideal for producing the aggregates used in concrete mixes that will perform well in the local climate conditions. Local sourcing of raw materials will aid in creating a more sustainable project while ensuring consistent material quality and availability.

Installation Considerations

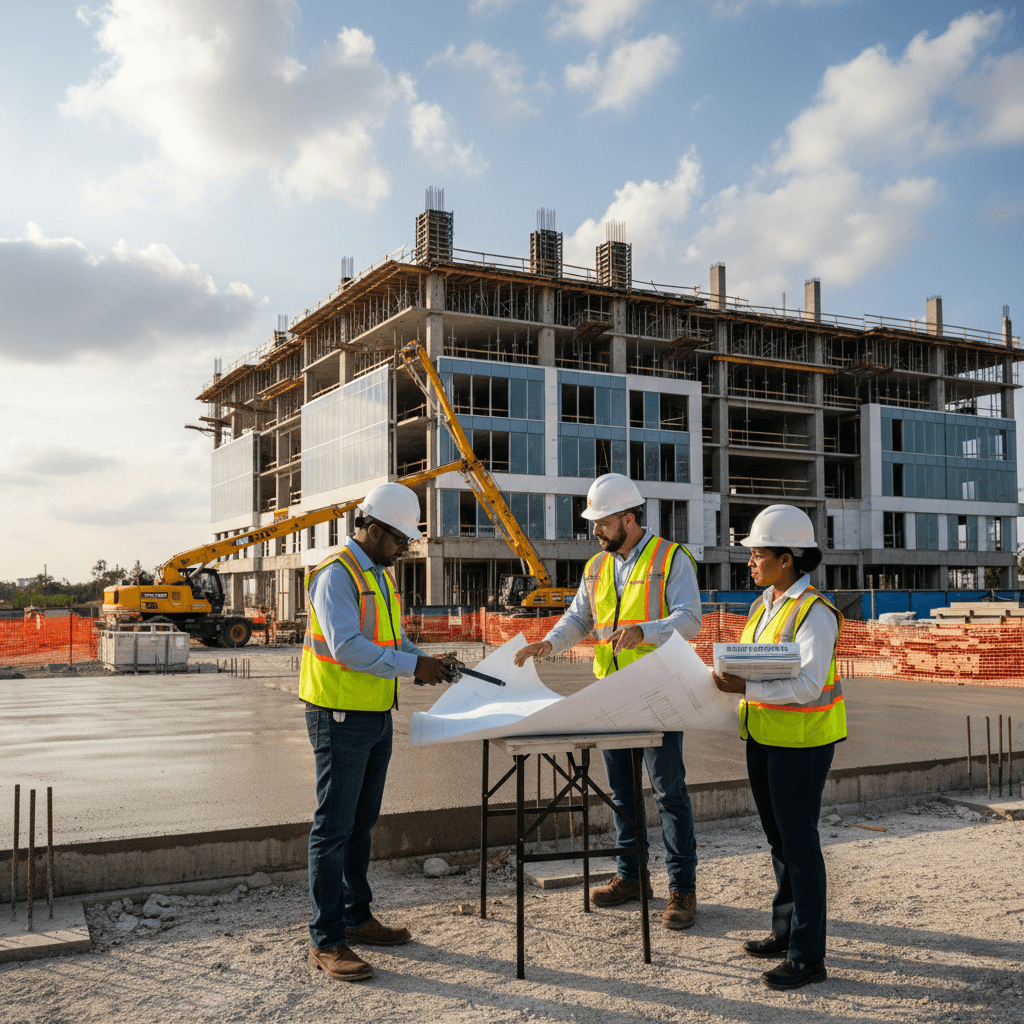

The successful installation of flatwork requires the coordination of the specified mix design characteristics and the procedures used to place the concrete to achieve the maximum possible results. Contractors must be aware of the relationship between the characteristics of the mix and the techniques used to finish the concrete, the procedures used to cure the concrete, and the timing of the placement of joints. Proper equipment selection and training of personnel will ensure that the benefits derived from the mix design are realized in the final placed concrete.

Monitoring weather conditions and developing contingency plans will assist the contractor in maintaining the quality of the concrete, even in adverse environmental conditions. During hot-weather concreting operations, the contractor may need to employ cooling measures, such as ice, evaporative retarders, or shade covers, to maintain the workability of the fresh concrete and to prevent surface defects.

At Doral Concrete Works, we combine our extensive knowledge of the local market and our state-of-the-art capabilities in designing concrete mixes to produce superior flatwork installations throughout the region. We take a comprehensive approach to evaluating the unique needs and requirements of each project, including environmental factors and performance expectations, to develop the best possible concrete formulation for each specific application. Whether it is a residential driveway or a commercial parking facility, we strive to provide the highest-quality, longest-lasting, and aesthetically pleasing concrete surfaces that meet the budgetary needs of each client. Through our Quality Control processes and our professional installation practices, we can assure that the specified mix design will provide superior performance and meet the expectations of each client for years of dependable service in South Florida’s demanding environmental conditions.