Sealing Stamped Concrete in Doral’s Coastal Climate

Stamped Concrete Doral

Protective measures for stamped concrete installations in Doral require a specific understanding of the unique conditions that exist as a result of being located near a large body of saltwater (coastal). The presence of salt air from the coastal areas results in an excessive amount of sodium chloride that is able to penetrate the pores of the stamped concrete and increase the rate at which the deterioration occurs. This is where professional application of protective coatings, along with regular maintenance, will provide extended life to these decorative systems as well as maintain their aesthetic appearance. Understanding the corrosion process allows for the implementation of effective means of protecting the decorative surface prior to visual signs of damage occurring. Implementing a maintenance schedule in conjunction with utilizing high-quality sealers will protect your investment for years to come in this difficult-to-protect coastal climate in Doral.

Impact of Coastal Environment on Stamped Concrete

Stamped concrete is exposed to excessive amounts of sodium chloride brought into the interior via ocean winds and humid air masses in a coastal setting. Sodium chloride enters the porous surface structure of the stamped concrete, where it reacts with calcium hydroxide in the cement paste to form calcium oxychloride crystals, which will expand and deteriorate the concrete matrix. The process is accelerated by variations in temperature and moisture movement through capillary systems in the concrete due to fluctuation in moisture and dissolved salts.

Additionally, South Florida’s high humidity creates prolonged exposure of moisture to the concrete, thereby maintaining moisture within the pores of the concrete longer than normal. Frequent rainfall also transports salt into the concrete structure at greater depth and causes additional freeze-thaw stress, which further degrades the integrity of the concrete.

These environmental factors are common to properties located throughout the White Course Park and other locations in the area.

Mechanisms of Chemical Degradation

Degradation caused by salt begins with the formation of ettringite crystals as sulfates react with calcium aluminate compounds present in cement. As ettringite crystals grow, they develop internal pressure, causing micro-cracking throughout the concrete matrix. Acidic conditions then reduce the pH of the concrete from its natural alkaline condition, thereby dissolving key binder components of the concrete that provide structural integrity.

This process becomes self-sustaining as the cracks formed in the concrete provide pathways for additional salt penetration and retain additional moisture. Early signs of this type of degradation may be surface scaling, spalling, and discoloration of the stamped concrete. By understanding how salt affects concrete, property owners near Veterans Park and the surrounding areas can take preventative action before irreversible damage occurs.

Methods and Products Used in Sealant Applications

Penetrating sealants have provided the most successful long-term protection for stamped concrete subjected to coastal corrosion. Penetrating sealants bond to the inside walls of the concrete pores to create an impervious barrier to water and salt. In contrast to surface coatings, silane and siloxane-based penetrating sealants can penetrate up to 2–4 mm into the concrete and still allow for breathability of the concrete. A quality penetrating sealer will provide a chloride screen that prevents salt from entering the concrete.

Topical acrylic coatings provide additional benefits to decorative stamped concrete surfaces, such as color retention and glossy appearance;e, however, topical coatings must be reapplied 1–2 times per year, whereas penetrating sealers can remain effective for 3–5 years. Contractors consider several variables to select the best combination of sealants for a particular job to meet the needs of the client (protection, aesthetics, and maintenance).

Advanced Sealer Technologies

Hybrid sealers containing reactive penetrating agents combined with film-forming agents are the newest generation of coastal concrete sealers. Hybrid sealers provide both deep penetration and surface enhancement, along with improved salt and UV resistance. Some hybrid sealers contain crystalline additives that self-heal minor cracks.

Maximum protection of high-traffic decorative stamped concrete surfaces can be achieved with polyurethane and polyaspartic coating systems. Polyurethane and polyaspartic coatings create an impermeable barrier to water and salt and provide excellent abrasion resistance. Property owners who live near the Laelanie Art Gallery and cultural district benefit from premium coating systems that protect their decorative concrete surfaces and maintain their appearance.

Preparation and Timing of Sealant Applications

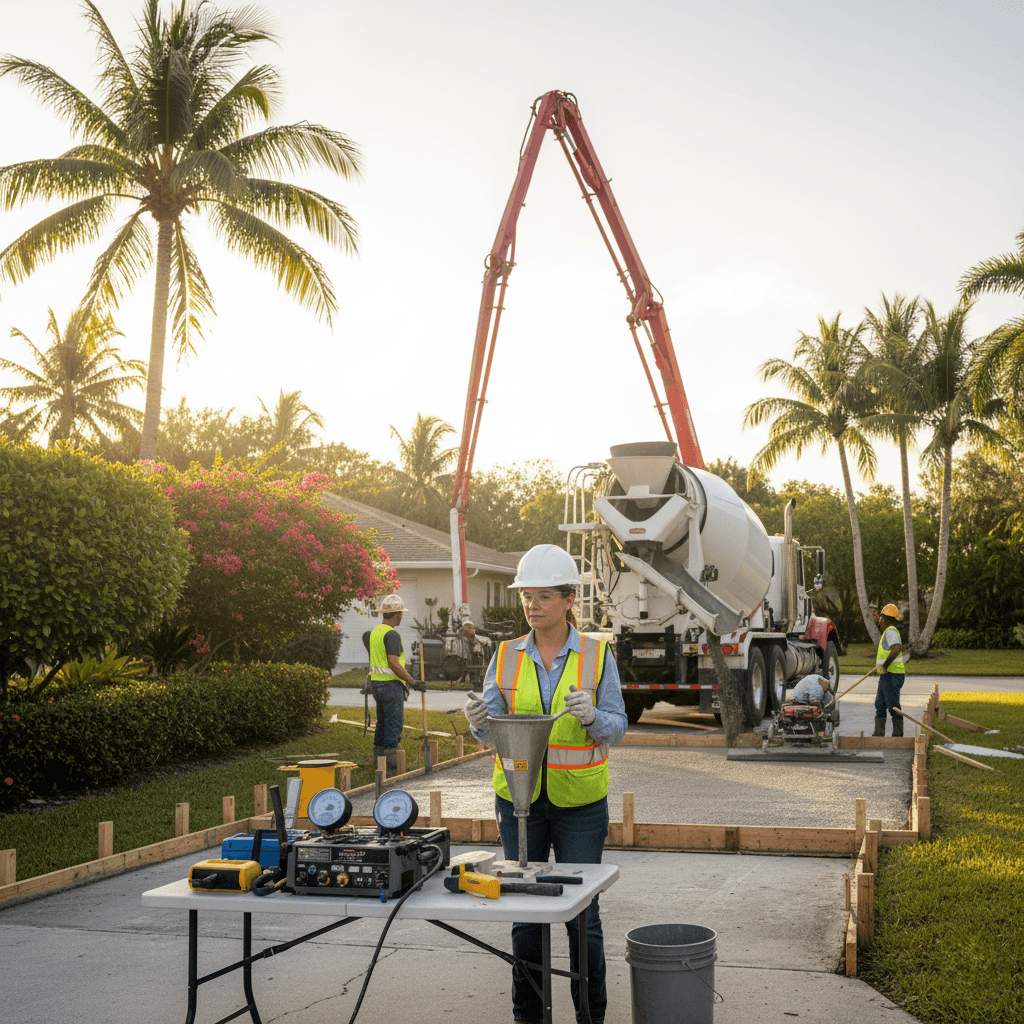

In order to successfully apply a sealer, the surface must be thoroughly prepared prior to application. Preparation includes cleaning, drying, and pH testing to ensure an ideal bonding environment. Contractors use specialized equipment to clean, remove old sealants, and remove surface irregularities that could impact new sealer performance. Moisture content testing is also required to verify that the concrete is dry enough for sealer application to begin.

The timing of application takes into consideration both the age of the concrete and the current environmental conditions to maximize sealer penetration and cure time. New decorative concrete installations should be allowed to cure for 28 days before applying a sealer, whereas existing decorative concrete surfaces must be cleaned and etched to open the pores of the concrete for sealer penetration.

Weather Conditions Impact Application Success and Performance Characteristics

Specialized equipment used for application purposes is designed for even coverage and controlled penetration rates. Spraying with low-pressure sprayers equipped with variable fan patterns ensures coverage is even and uniform without over-applying the sealer, which can result in a surface film or bubbling. Using back-rolling techniques aids in achieving even coverage on all textured decorative stamped surfaces with deep joint patterns and relief details.

Applying multiple thin coats of sealer usually produces better results than one heavy coat. Applying thin coats of sealer allows the sealer to penetrate properly and cure between each layer. Professional contractors monitor the weather and adjust their application techniques accordingly, avoiding application when high temperatures and/or direct sunlight occur, which can result in premature surface drying and poor penetration.

Scheduling and Conducting Maintenance

Regularly scheduled inspections are essential in identifying early signs of sealer degradation prior to losing the protective qualities of the sealer. Evaluations of surface water absorption, color retention, and appearance assist in determining when to reapply a sealer. Visible signs of sealer degradation include increased surface water absorption, color loss, and surface texture changes that indicate reduced protection.

Annual cleaning of decorative concrete surfaces removes accumulated salt deposits, organic matter, and surface debris that can lead to sealer degradation. Cleaning should not utilize pressure washing that can damage the sealer and open the pores of the concrete to increased salt penetration. Use of suitable chemical cleaners and gentle cleaning techniques helps preserve sealer integrity while maintaining the cleanliness of the surface.

Monitoring Environmental Factors and Making Adjustments

Properties located in coastal areas must pay closer attention to environmental factors during hurricane season and increased salt exposure due to storm surge and wind-driven spray. Post-storm assessments of damaged surfaces and contamination can aid in identifying damage that may require immediate attention to prevent continued degradation. Assessments will determine if emergency cleaning or reapplying a sealer will provide sufficient protection or if more extensive restoration will be needed.

Adjustments to seasonal maintenance practices take into consideration varying degrees of environmental stresses that occur throughout the year and increased frequency of maintenance activities during warmer months when temperature and humidity accelerate chemical reactions. Property owners living in the Doral Cultural Arts Center area can benefit from customized maintenance plans that address specific environmental exposures and usage patterns.

Cost vs. Benefit Comparison of Protecting Decorative Concrete Professionally

Protecting decorative concrete professionally using sealing and maintenance practices offers significant returns on investment by eliminating the expense associated with repairing or replacing damaged surfaces. Quality sealing applications typically range in cost from $2 to $6 per sq ft, whereas total replacement costs for decorative concrete can exceed $15 to $25 per sq ft. Decorative concrete sealed regularly can increase the lifespan of the surface by 200% to 300% and continue to enhance the appearance of the property.

Comparatively, long-term costs associated with protecting decorative concrete professionally far outweigh the costs of reactive repair practices that attempt to restore damaged surfaces after the fact. Budgeting for regular maintenance provides a means of allocating funds for the protection of the surface, whereas reactive repair practices can be expensive and require premium pricing for emergency repairs.

Protection of Property Values

Decorative concrete surfaces, maintained properly, add substantial value to a property and its marketability in the competitive South Florida residential real estate market. Maintaining a decorative concrete surface properly will continue to maintain the owner’s investment in the surface while demonstrating responsible property stewardship that attracts potential buyers. Documented maintenance records are useful for supporting warranty claims and insurance coverage related to weather damage.

Properties with properly protected decorative concrete surfaces will generally sell at a higher price point than those with improperly protected surfaces or those requiring restoration work. Photographs and documentation of maintenance performed on decorative concrete surfaces provide valuable evidence that supports appraisals of the property and illustrate the owner’s continuing investment in property improvements and preservation.

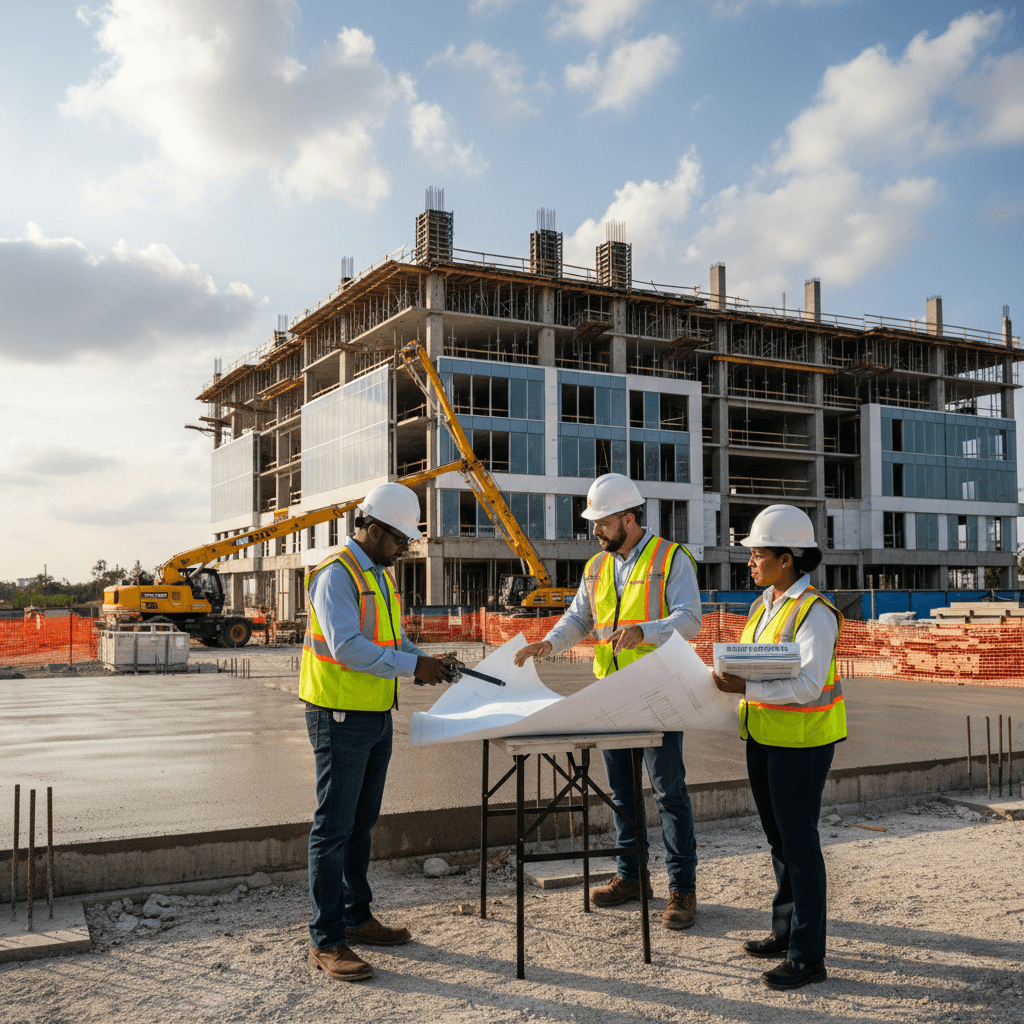

Doral Concrete Works specializes in comprehensive decorative concrete protection programs designed specifically for the extreme coastal environment found in South Florida. Our experienced staff combines the latest advancements in sealer technology with proven application techniques to provide superior protection to decorative concrete surfaces while maintaining their attractive appearance. From surface preparation through maintenance scheduling, we provide complete decorative concrete protection solutions that will extend the life of your decorative concrete surfaces and minimize your long-term expenses. Whether you are looking to protect new decorative concrete surfaces or restore existing surfaces, our staff has the knowledge and expertise to provide the best possible solution to protect your decorative concrete surfaces from the extreme environmental factors found in the Doral area while maintaining their attractive appearance.